Drilling into hard materials isn’t forgiving. One weak component can slow everything down, rack up costs, or stop a project cold. That’s where spezialbohrgetriebe come into play. These specialized drilling gearboxes deliver power with control, even when conditions push machines to their limits.

This guide walks you through what spezialbohrgetriebe are, how they work, where they’re used, and why they outperform standard solutions. If you deal with drilling equipment, this is knowledge you can actually use.

What Is a Spezialbohrgetriebe?

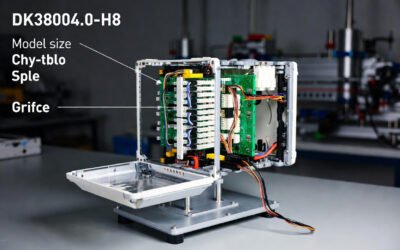

A spezialbohrgetriebe, or special drilling gearbox, is a purpose-engineered transmission system designed specifically for drilling operations that demand high torque, precision, and endurance. Unlike standard gearboxes that serve general industrial tasks, spezialbohrgetriebe are built to survive extreme mechanical stress over long operating periods.

In practical terms, these gearboxes manage how power flows from the motor to the drill bit. They adjust speed and torque so the drill cuts efficiently without stalling, overheating, or losing accuracy. This becomes critical when drilling through rock, concrete, metal, or other dense materials.

What truly sets a spezialbohrgetriebe apart is customization. Engineers design each unit around the drilling task itself. Load requirements, drilling depth, environmental exposure, and duty cycles all shape the final gearbox. That level of specialization explains why these systems appear in heavy construction, mining, energy exploration, and precision manufacturing rather than everyday machinery.

How Spezialbohrgetriebe Work

At a glance, a spezialbohrgetriebe may look like a solid metal housing with a few shafts. Inside, however, precision engineering does the heavy lifting.

Power enters the gearbox from an electric, hydraulic, or diesel motor. Inside, a series of gears reduces speed while multiplying torque. This controlled conversion allows the drill bit to maintain consistent force, even when material resistance changes suddenly.

Multiple gear stages help spread loads evenly. Bearings stabilize rotating parts. Lubrication systems reduce friction and carry away heat. Together, these elements create smooth power transfer and minimize vibration, which protects both the drilling tool and surrounding components.

The real advantage shows up during continuous drilling. Where standard gearboxes overheat or wear out, spezialbohrgetriebe maintain performance hour after hour. That reliability keeps projects moving and reduces unplanned downtime.

Engineering and Design Principles

Every spezialbohrgetriebe starts with application-specific engineering. Designers don’t guess. They calculate.

Gear Configurations

Different drilling tasks require different gear layouts:

-

Planetary gears deliver high torque in compact spaces

-

Bevel gears redirect power when drilling angles change

-

Worm gears provide smooth, controlled motion at low speeds

Each configuration solves a specific mechanical challenge, whether space constraints, torque demands, or precision requirements.

Materials and Construction

High-strength steel alloys form the backbone of these gearboxes. Heat treatment and surface hardening protect gear teeth from fatigue. Heavy-duty housings resist deformation, while advanced sealing systems block dust, water, and debris.

The result is a gearbox designed to operate reliably in environments that destroy ordinary equipment.

Applications of Spezialbohrgetriebe

Spezialbohrgetriebe thrive where failure is expensive or dangerous.

Construction and Civil Engineering

Foundation drilling, tunnel boring, and deep anchoring rely on gearboxes that deliver steady torque under massive loads.

Mining and Quarrying

Dust, shock loads, and continuous operation define mining environments. Spezialbohrgetriebe handle these conditions without sacrificing performance.

Oil, Gas, and Geothermal Energy

Deep drilling demands absolute reliability. These gearboxes support long drilling runs where downtime costs millions.

Manufacturing and Aerospace

Precision drilling for high-value components requires gearboxes that deliver exact speed control with minimal vibration.

Advantages of Spezialbohrgetriebe

Using a spezialbohrgetriebe offers clear benefits:

-

Higher torque without sacrificing control

-

Longer service life under extreme loads

-

Reduced vibration and improved drilling accuracy

-

Lower maintenance costs over time

Think of it like a custom engine tuned for one race. Generic gearboxes simply can’t compete.

How to Choose the Right Spezialbohrgetriebe

Choosing the wrong gearbox costs time and money. Choosing the right one pays dividends.

Start by defining torque requirements, operating speed, and expected load cycles. Consider environmental factors like dust, moisture, and temperature. Evaluate how the gearbox integrates with existing equipment.

Avoid oversizing. Bigger isn’t always better. The goal is efficiency, not brute force.

Maintenance and Longevity

Even the best spezialbohrgetriebe needs care. Regular lubrication checks, temperature monitoring, and vibration analysis prevent small issues from becoming failures.

Modern designs increasingly include sensors that support predictive maintenance. Instead of reacting to breakdowns, operators can schedule service before problems escalate. That approach dramatically extends gearbox life and improves operational planning.

Future Trends in Spezialbohrgetriebe

The future points toward smarter systems. Integrated monitoring, data-driven maintenance, and modular designs will make spezialbohrgetriebe even more efficient. Sustainability also plays a growing role, with designs focused on reduced energy loss and longer component lifespans.

As drilling projects grow deeper and more complex, demand for specialized gear solutions will only increase.

Conclusion

Spezialbohrgetriebe are more than mechanical components. They are precision tools built for the toughest drilling challenges imaginable. Through custom engineering, durable materials, and intelligent design, they deliver power exactly where it’s needed.

If your drilling operation demands reliability, accuracy, and long-term efficiency, a spezialbohrgetriebe isn’t a luxury. It’s the right tool for the job.